Exploring: Sustainability, DOE 436.1 & More!

Can a seemingly innocuous stainless steel hold the key to both industrial advancement and environmental responsibility? The answer, surprisingly, lies in the versatile properties of a specific alloy, its development, and its impact on modern industries, all encapsulated within the designation: 436.

The pursuit of progress often hinges on the optimization of materials. While the language of technical specifications and departmental orders may seem dry, the implications of these documents are far-reaching. Consider, for instance, the seemingly simple mandate: "Target fugitive emissions gases 22 include carbon dioxide (co2), methane (ch4), nitrous oxide (n2o), hydrofluorocarbons." This is not just a bureaucratic statement; it underscores a global effort to combat climate change. Simultaneously, within the realm of industrial materials, the ongoing refinement of stainless steel alloys represents a constant quest for improved performance, durability, and efficiency. The interaction of these two seemingly disparate fields creates an intricate landscape where innovation and responsibility intersect.

| Name/Designation | 436 Stainless Steel |

| Type | Ferritic Stainless Steel |

| Composition | Primarily iron and chromium, with additions of molybdenum and niobium. |

| Key Properties | Excellent corrosion resistance, good formability, enhanced resistance to oxidation and high temperature. Reduces drawing and wrinkling during forming. |

| Primary Applications | Various industrial and commercial applications where corrosion resistance and formability are critical. Exact applications would vary. |

| Development Context | An improvement over grades 430 and 434 stainless steel, designed to address limitations in formability and high-temperature performance. |

| Relevant Regulatory Context | Indirectly linked to initiatives promoting environmental sustainability, such as those related to emissions reduction. The focus on efficiency and durability aligns with broader goals of resource conservation and waste reduction. |

| Historical Context | Evolved through continuous material science advancement. The development represents incremental progress in materials science. |

| Impact and Significance | Provides a more robust and reliable material choice that can extend the lifespan of equipment, potentially reducing replacement rates and associated environmental impacts. Improved formability simplifies manufacturing processes. |

| Reference Website | MatWeb - Data Sheet for Stainless Steel 436 (Please note: Replace this with an appropriate, reliable materials science website that offers detailed information on 436 stainless steel.) |

Departmental sustainability and efficient resource management are becoming increasingly important. The directives, such as "Doe o 436.1, departmental sustainability (ipt) background documents," and "Doe order 436.1 departmental sustainability," point towards a systematic approach to integrating environmental consciousness into governmental and industrial operations. These initiatives seek to minimize environmental impact while concurrently enhancing operational efficiency. This is further reflected in the promotion of "sustainable, efficient, reliable, and resilient energy for the future." The goal is clear: to secure a sustainable future.

The evolution of materials science, coupled with the relentless pursuit of sustainability, has led to advancements like stainless steel 436. This ferritic stainless steel, with its specific composition of iron, chromium, molybdenum, and niobium, possesses excellent corrosion resistance and good formability. The addition of molybdenum and niobium is especially crucial, as it addresses the "drawing" or "wrinkling" challenges encountered during forming, a significant improvement over its predecessors, 430 and 434. Simultaneously, this composition enhances resistance to oxidation and high temperatures, thereby increasing the durability and lifespan of components and equipment. The material science demonstrates a clear connection between materials, manufacturing, and long-term sustainability.

Consider the context of the United States Department of Energy (DOE) and its operational orders: "The subject order was issued on april 25, 2023, and cancels/supersedes doe order 436.1 dated may 2, 2011." These directives, particularly in their current form, emphasize the need to refine processes, enhance sustainability, and minimize environmental impact. They often relate to the reduction of greenhouse gas emissions, improved energy efficiency, and the overall conservation of natural resources. These internal initiatives mirror larger global movements.

Within this ecosystem, the choice of materials like 436 becomes vital. The enhanced durability and corrosion resistance inherent in 436 contribute directly to the longevity of components, reducing the frequency of replacements and lessening the demand for raw materials. The implications of these advancements extend far beyond materials science, influencing entire sectors. Its superior performance, for example, enhances efficiency and directly ties into the broad aims of sustainability and resource conservation.

The directives often encompass areas such as energy efficiency, waste reduction, and environmental protection. The focus on "advances [in] sustainable, efficient, reliable, and resilient energy" is particularly significant. The principles enshrined in these orders have a direct impact on the materials used and the processes employed across various industries.

The drive for efficiency is a constant in modern business, as reflected by the statement, "It emphasizes efficiency, accuracy, and adaptability, making it an ideal solution for modern businesses." This pursuit of efficiency is also inherent in the materials we choose, as 436 stainless steel is designed to be more efficient in its production and use. These initiatives reflect an understanding that sustainability and operational efficiency are two sides of the same coin. This also leads to the reduction of costs and also less environmental impact.

The digital world also has a role in this pursuit. While the material science of 436 is very different from the digital world, it shares the same core values. This can be seen when we look at examples such as "Docker \u4e0a\u306e sql server 2019 \u306b\u3001vscode \u3067\u63a5\u7d9a\u3057\u30af\u30a8\u30ea\u30fc\u3092\u5b9f\u884c\u3057\u3066\u307f\u305f\u3002\u81ea\u5206\u7528\u30e1\u30e2\u3002\u624b\u9806\u4e0b\u8a18\u306e\u30c1\u30e5\u30fc\u30c8\u30ea\u30a2\u30eb\u306b\u5f93\u3063\u3066\u3044\u3051\u3070ok\u3002" which can be roughly translated to "I tried connecting to SQL Server 2019 on Docker with VSCode and executing a query. A memo for my own use. Following the tutorial below is okay." This shows how technology is used to achieve more with less resource.

Digital tools are increasingly important for efficiency and data driven decision making. "As a powerful tool, done436 offers an extensive range of information that caters to diverse interests and inquiries, ensuring users are equipped with the most relevant and updated data." This highlights the importance of data, as a tool to enable informed decisions. Similarly, the use of software to improve manufacturing helps improve the production process.

The role of individuals and organizations within this system is essential. The "Director, contract and financial assistance policy division, office of policy, office of acquisition management," for instance, are key players in enforcing and interpreting policies. Their responsibility involves aligning material procurement with sustainability mandates. It's a multifaceted system where each element plays a critical role.

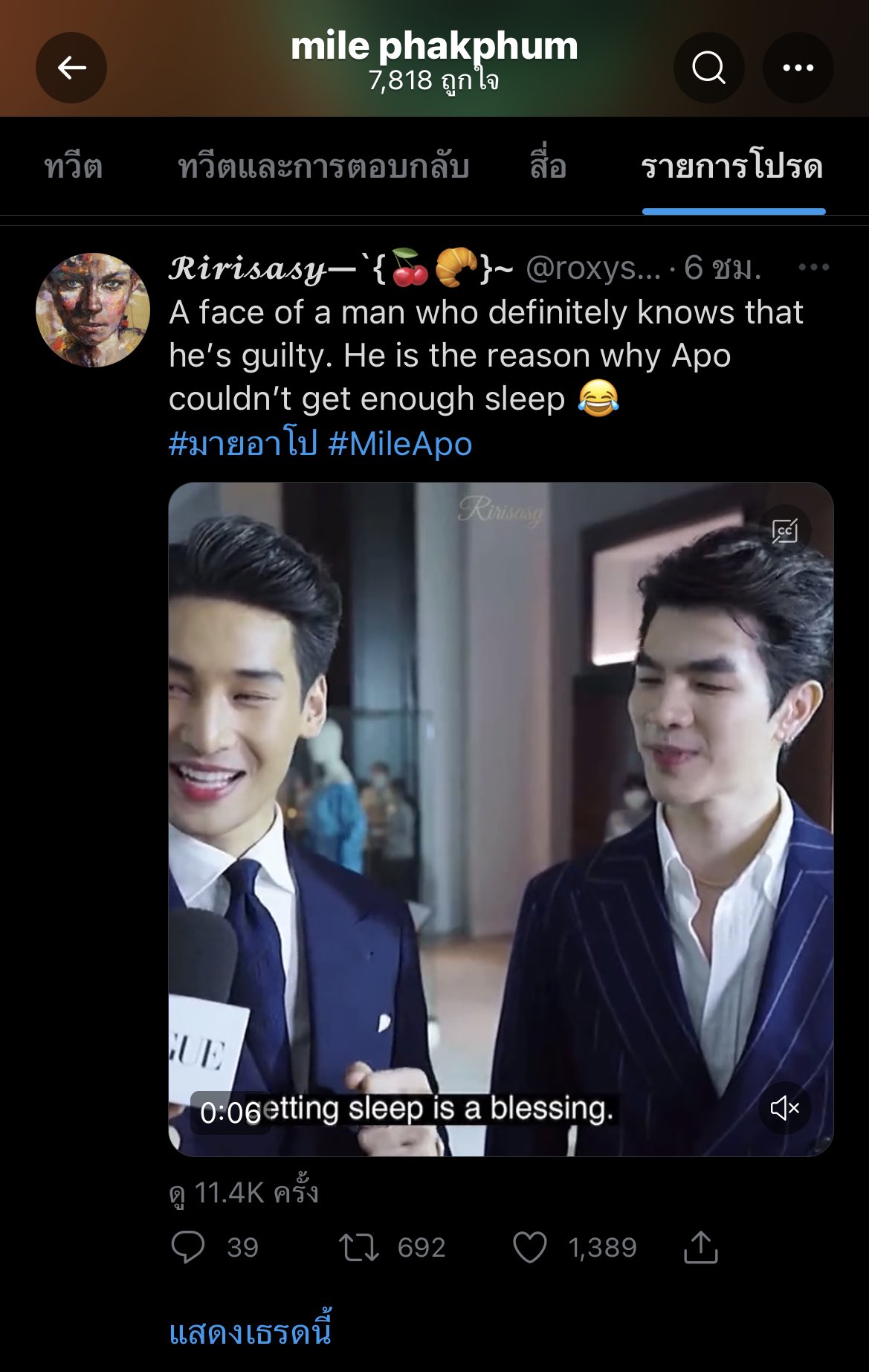

The social media landscape, as demonstrated by entries like "Mec (@done436) / twitter #reviewidept," shows how information can flow outside of the corporate and government world. This also shows the impact, and the relevance. This also highlights the need for open communication, transparency, and sharing insights regarding sustainability and resource management.